T.A.M. S.r.l. PRODUCTS

SCREW COMPACTORS, SCREW CONVEYORS, CLARIFIERS, CLARIFIERS, SLUDGE DEHYDRATION THICKNESSES, POLYELECTROLITY PREPARATION STATIONS, SLIDERS

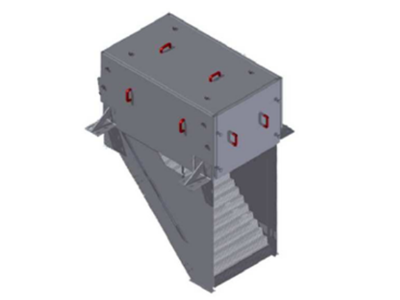

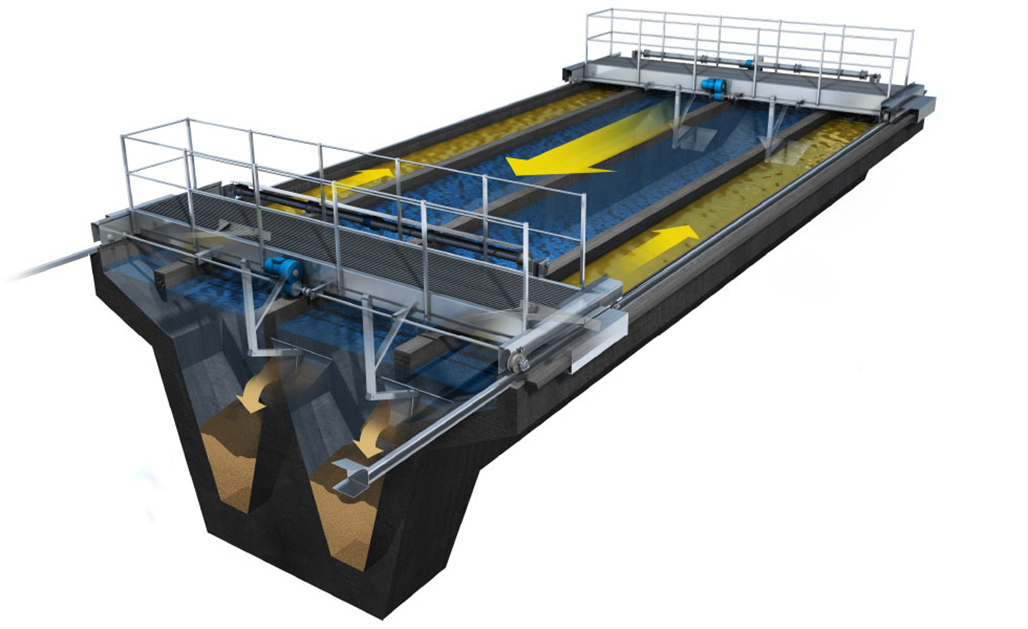

SAND CLASSIFIER

The sand classifier is a machine used for the separation and classification of the sands present in the waste water of various sources, both civil and industrial.

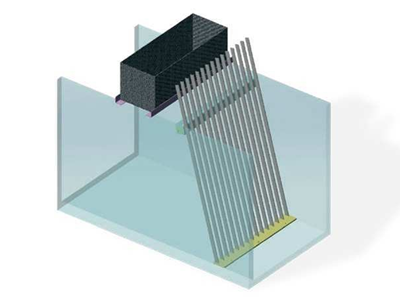

SAND WASHING

Conical washer. They are classifiers suitable for the separation, classification and washing of the sand present in the waste water of various origins: from municipal purification to industrial purification of various types.

"VORTEX" SANDBLASTER

It is an equipment used for the separation of sands; it is installed in circular tanks and, thanks to the centrifugal action of the blades, the sands settle and are extracted by Air-Lift.

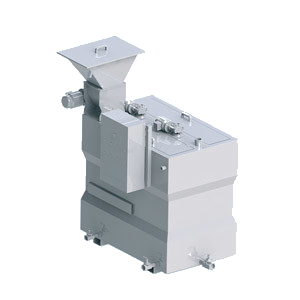

SCREW COMPACTOR WITHOUT SHAFT

It is a combined machine that allows three operations at the same time: drainage, conveyance, compaction.

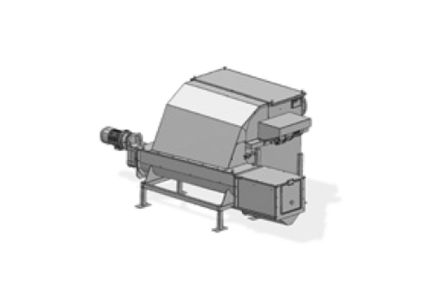

COMPACTOR - SCREW WASHER

The screw compactor with shaft allows three types of operations: drainage, transport, compaction. The compaction values are higher than the “shaftless auger compactor” model.

SCREW FILTER WITH COMPACTOR

Combined screw filter for the separation and compaction of the solids present in the wastewater from municipal and industrial plants of various kinds.

SCREW FILTER WITHOUT COMPACTOR

Combined screw filter for the separation of the solids present in the wastewater from municipal and industrial plants of various kinds.

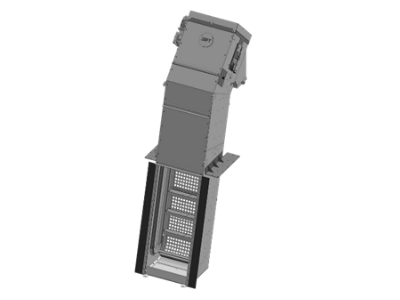

SCREW FILTER WITH COMPACTOR WITH CONTAINER

Screw filter with compactor in container.

The screw filter is equipped with a completely watertight stainless steel container to allow installation where the concrete channel is not foreseen.

SCREW FILTER WITHOUT COMPACTOR WITH CONTAINER

The screw filter is equipped with a completely watertight stainless steel container to allow installation where the concrete channel is not foreseen.

SCREW FILTER FOR FLOWS WITH HIGH SOLID CONTENT

The screw filter is used for the treatment of wastewater with a significant percentage of solid to be separated.

END GRID WITH ROTATING DRUM

It consists of a steel body inside which a drum filter in a round hole / wedge wire rotates.

The wastewater flows into the supply tank through a flanged drain and is conveyed to the external surface of the filter drum.

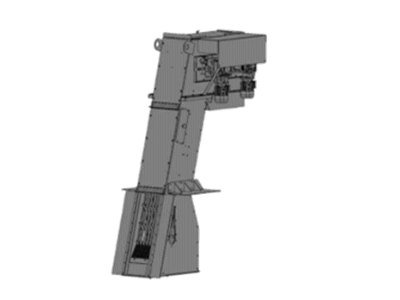

ROTATING DRUM FINE GRID WITH INTEGRATED COMPACTOR

It consists of a steel body inside which a drum filter in a round hole / wedge wire rotates.

The waste water flows inside the supply tank, through a flanged drain and is conveyed to the external surface of the filter drum.

The separated solids continue to the integrated compactor screw and are discharged laterally.

CHANNEL COMB GRILL

It is a grate specially designed for the coarse screening of sewage entering the plant.

Thanks to the filter screen, consisting of the fixed bar grid, this machine is able to block suspended solids larger than the filtration opening and lift them by means of cleaning combs.

CHANNEL BRUSHED GRILL

It is specially designed for medium - fine screening of sewage entering the plant.

Thanks to the filter screen consisting of a perforated mesh, this machine is able to block suspended bodies.

ROTATING BELT GRID

Self-cleaning belt system with ABS chain rotation.

Continuous belt cleaning with upper rotating brush.

External structure in stainless steel.

GRID WITH STEPS

The step grate is used in solid / liquid separation operations, as a system for removing debris and suspended solids from liquids.

Typical use is for water treatment and purification plants, where effective primary filtration ensures efficient operation of downstream processes.

MANUAL CHANNEL GRID

The manual channel grate is composed of a grate fixed to the reinforced concrete channel, for cleaning by means of a rake and a container for the grilled material.

According to operational needs, the operator will have to periodically clean the material deposited on the grid using the rake.

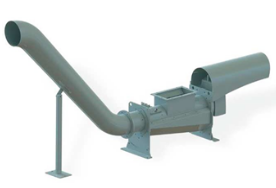

AUGER CONVEYOR WITHOUT SHAFT

It consists of a coil without internal central shaft that rotates inside a trough (tubular or with U-section) with one or more loading hoppers and one or more unloading openings.

AUGER CONVEYOR WITHOUT VERTICAL SHAFT

It consists of a coil without an internal central shaft that rotates inside a trough (tubular or with U-section).

AUGER CONVEYOR WITH INTERNAL SHAFT

It consists of a spiral with a central shaft which, connected directly to the motor, rotates inside a channel or tube.

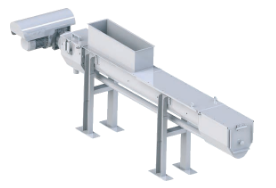

SCREW CONVEYOR

It is a machine that represents a special application of the conveyor concept: these are two conveyors without a central shaft that rotate inside a modular channel with a "W" section, each equipped with its own motorization, which can work independently or synchronized depending on the application.

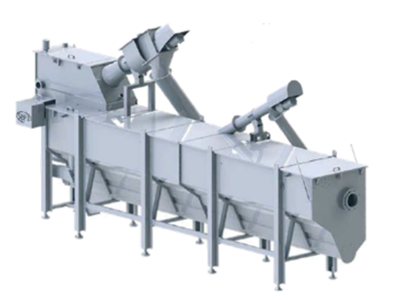

COMPACT SYSTEM FOR RECEIVING AND PROCESSING BOTTINI

It is a compact unit capable of carrying out the pre-treatment of screening, sandblasting and degreasing of waste water deriving from various types of industrial processes.

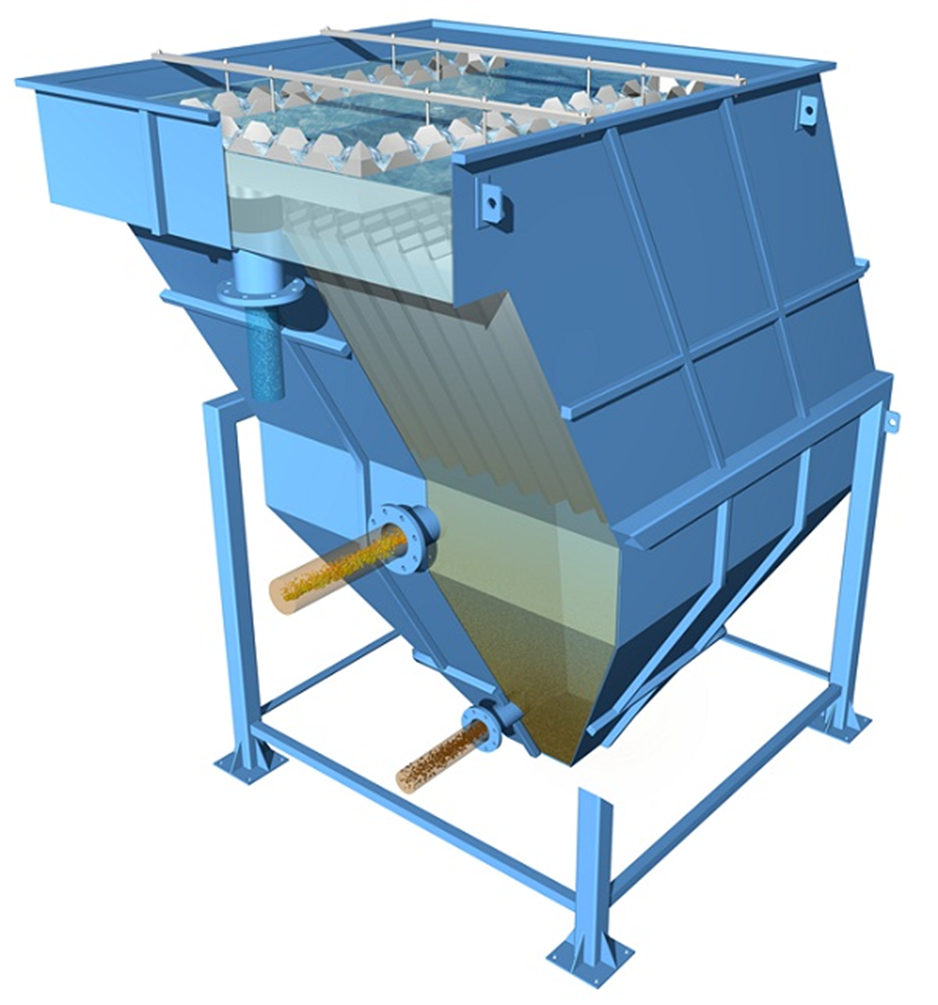

COMPACT PRE-TREATMENT PLANT

This combined machine is fed by a pump or by gravity, through a fixed pipe.

The wastewater passes through an auger filter which removes the largest solid particles, then reaches a sedimentation tank where the sedimented particles are then removed by a system of augers.

As an option, it is possible to install the system for removing grease and suspended oils.

SLIDERS

The gates are adjustable systems for the interception of the flow of fluids in channels or ducts in order to control the outflow and the flow rate.

LIME DOSING SYSTEM

Lime storage and dosing silos are used in drinking water treatment plants, waste water and industrial applications.

The most frequent use of the system is for the dissolution and preparation of lime emulsion or with mixing systems for dewatering or conditioning of the sludge.

MILK OF LIME DISSOLVER

The lime milk dissolver is a cylindrical tank where lime and water are introduced. Milk of lime is produced by means of a paddle stirrer.

LAMELLAR PACKS

The lamellar pack sedimenter is a system that allows water to pass through the lamellar pack housed inside a special containment tank that can be used with substances weighing less than that of water.

With the use of the lamellar pack settler it is possible to obtain both the sedimentation of sludge and the separation of non-emulsified oils.

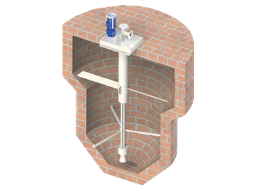

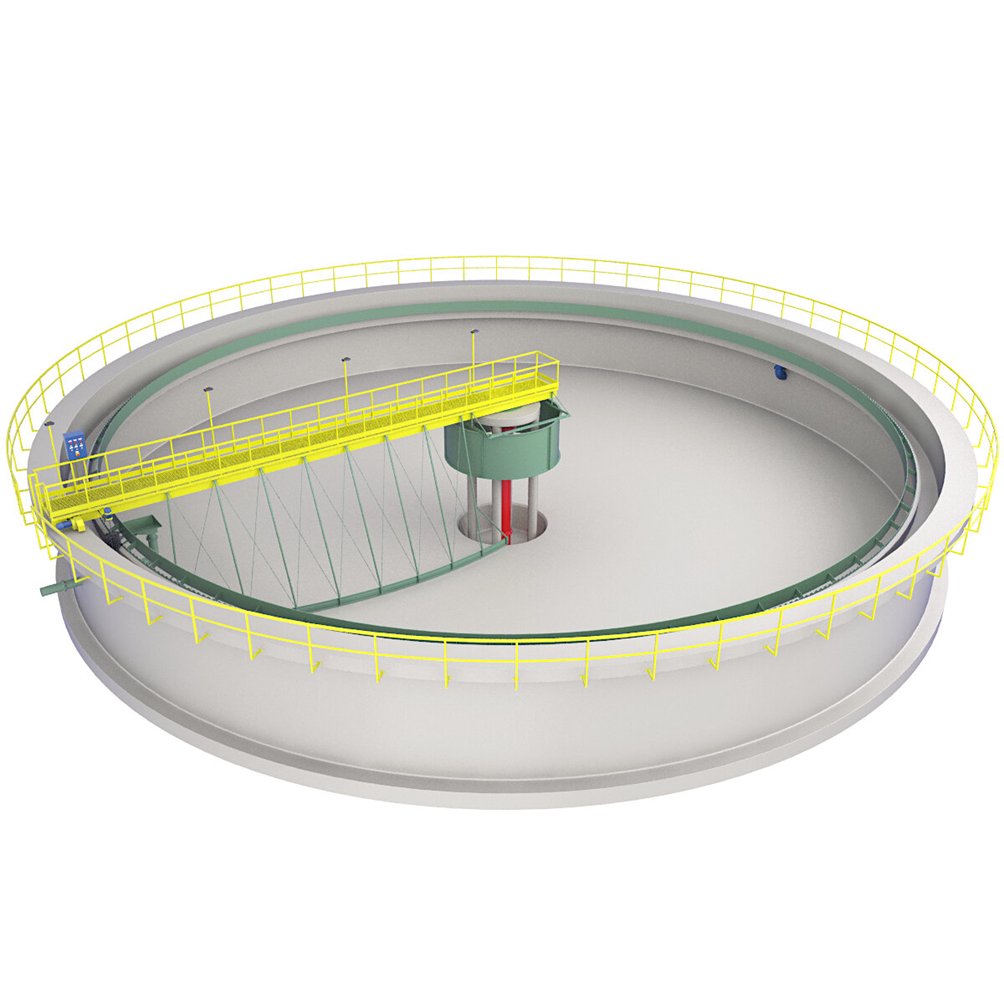

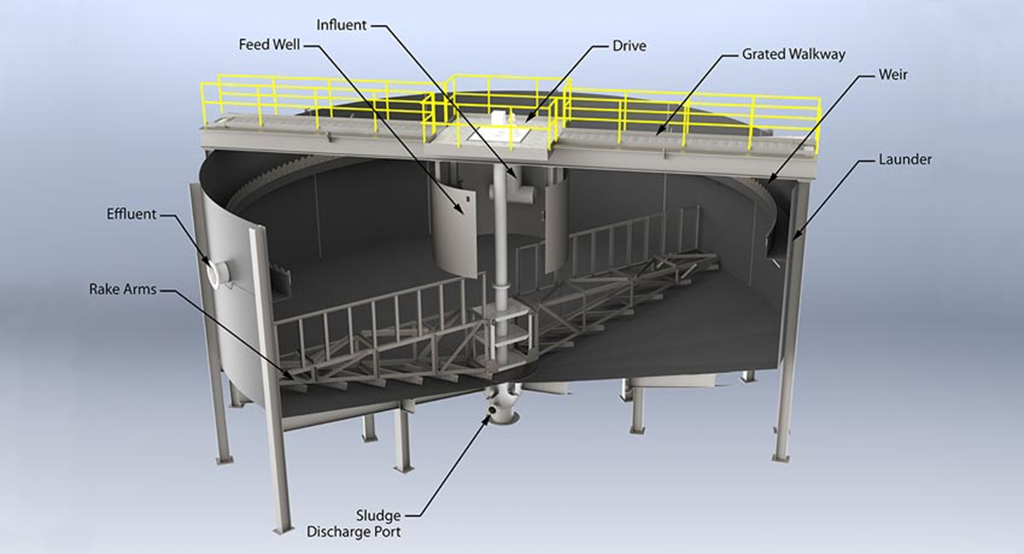

CIRCULAR CLARIFIERS

The scraper bridge is designed to be installed in all circular settling tanks (primary or secondary settling).

It is generally used for the treatment of urban or industrial wastewater that contains heavy substances that can settle quickly and in which it is important to be able to extract the sludge as it forms.

"GO AND COME" CRANE

The wastewater flows into the tank and the solids settle on the bottom. In the aspirated version the substances are scraped off by scraping blades and extracted with a pump.

The supernatants are scraped on the surface and removed through a foam collection channel.

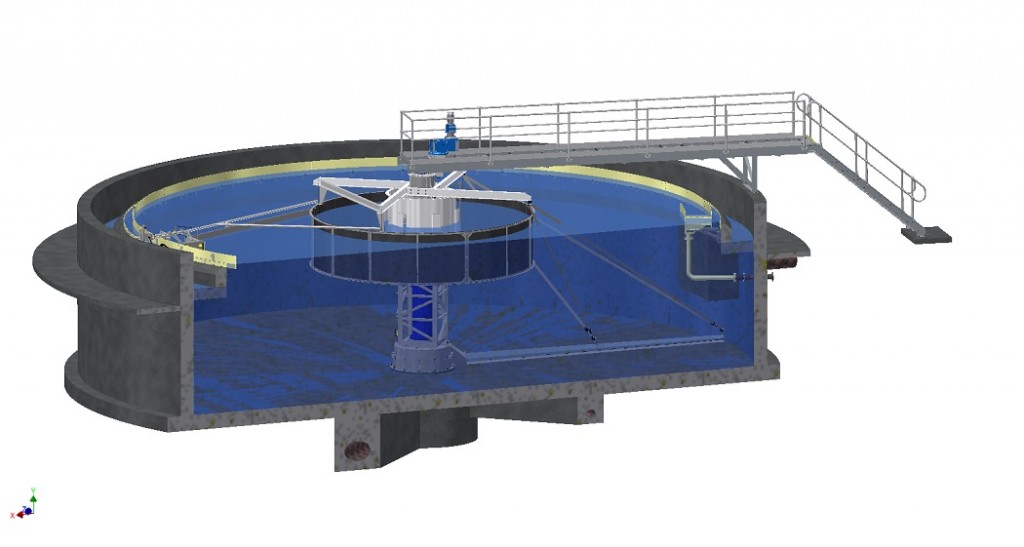

CLARIFLOCCULATORS

Clariflocculation is a chemical-physical treatment applied to the water to be treated or purified and consists mainly in the precipitation of suspended non-sedimentable substances (and, if present in solution, also sedimentable substances) which during this process gradually form larger aggregates and in weight until it forms a precipitate which settles on the bottom of the container or tank used.

This process allows the precipitation of non-sedimentable colloidal suspended solids, and also of very fine sedimentable solids, which are difficult to eliminate with a simple physical treatment due to their extremely low sedimentation rate which would require large sedimentation tanks or a need to stay too long. in the settler.

With clariflocculation, almost all particles that cause water turbidity can be separated by precipitation.

THICKNERS

Gravity thickeners generally consist of circular tanks with an inverted truncated cone bottom, with a flow pattern similar to that of the primary sedimentation tanks with a circular plan. In this case, however, since the concentration of the solids is higher than that of the wastewater, the sedimentation speed is considerably reduced and therefore the residence times of the sludge in the tanks are greater.

In the tanks, due to gravity, the sludge thickens, thus reducing its volume up to three or four times.

The decanters can be covered and kept in suction, and the sucked air is sent to the deodorization system.

FILTER PRESS

The filter press is an industrial machine used to dewater sludge by means of solid-liquid separation processes.

In other words, filter pressing is a system of volumetric reduction of liquid substances that have suspended solids inside.

The filter press is composed of a series of plates alternating with cloths which adhering to each other form chambers, in which the dehydrated mud cake is formed.

The sludge is pumped at high pressures into the filter.

The solid phase is retained in the cavities between plates and frames and the liquid phase, with a low content of suspended solids, exits from the filter press.

The subsequent recovery of the solid phase occurs with the opening of the filter press, when the sludge has filled the cavity (therefore the filter pressing process is a discontinuous process).

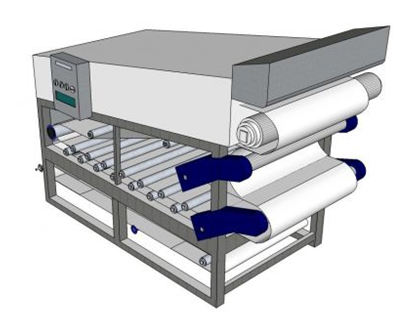

TAPE PRESS

The dewatering of sludge with the Nastropressa is carried out mechanically.

The mud is inserted between two filter belts which are passed between a series of rollers gradually narrower until a sheet of 2-3 cm is obtained.

The filter press works continuously and requires minimal assistance from the staff, it is aimed at reducing the volume and weight of the sludge by partial separation of the liquid component, in order to make them compatible with final disposal.

The achievable dryness levels are such as to give the mud the appearance of a loam (the mud is therefore defined as "palable", that is, capable of being moved by mechanical means) and characteristics suitable for allowing its final disposal, in landfills, through heat treatments and, where the conditions exist, through agronomic use.

NEW MODEL IN THE DESIGN PHASE

FLAT TABLES

Performs a gravity drainage of sludge, generally used upstream of digestion systems. They exploit the principle of gravity drainage allowing to concentrate up to ten times the content of suspended solids in the wastewater.

The mud, through the inlet flanged connection, reaches a static distributor which distributes it evenly on the surface of the moving sheet.

The water drains by gravity through the cloth and is collected in one or more tanks below. A system of plowshares turning the sludge creates additional spaces for filtration, facilitating and improving dehydration.

The dewatered sludge is discharged through a rectangular flange when it reaches the last horizontal section of the run of the sheet.

The cloth is washed along the lower return section towards the loading area of the machine, by means of a system of high pressure nozzles.

The washing water is then collected together with the drainage water in the tank below.

BURATTI

This equipment is used to mix and preliminarily dehydrate the mud, it mainly consists of a rotating filter drum with variable revolutions. The drum is supported by orientable bearings and equipped with a heat-shrinkable polyester filter cloth.

Thanks to the rotation of the drum, a large filtering area, which is continuously kept clean by a washing system, comes into contact with the mixed sludge.

This allows the water, separated thanks to the action of the polyelectrolyte, to filter through the cloth.

IN DESIGN

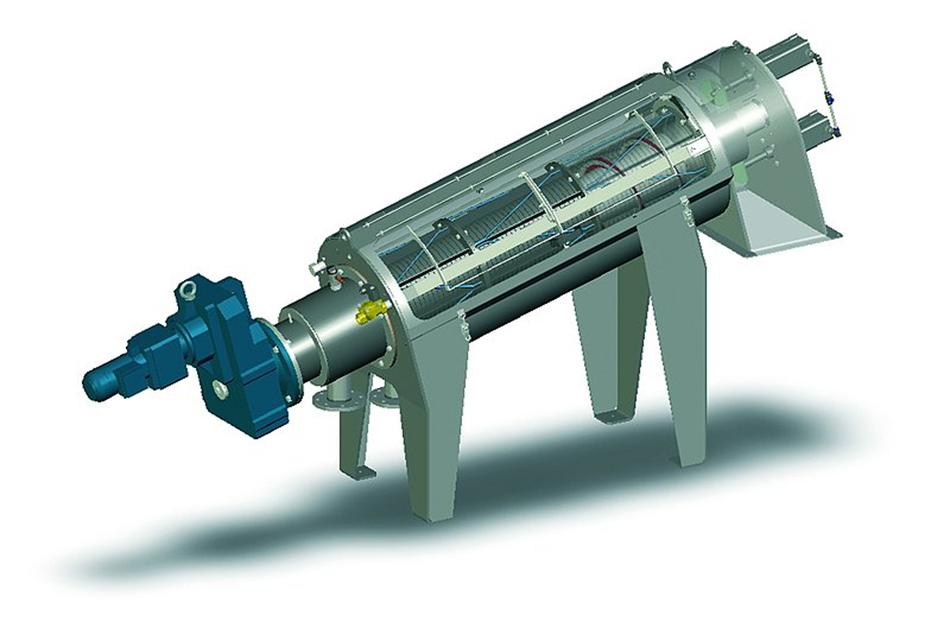

AUGER SLUDGE PRESS

It is designed to dewater sludge from municipal or industrial processes and achieve an average dewatering level of 20%.

The sludge is conveyed by an inclined spiral, first through a drainage chamber with progressive wedge wire spacing and then through the pneumatic pressing module.

There is a version of the screw press for slurry which also includes a sludge thickener module.

POLYELECTROLYTE PREPARATION STATIONS

Tank divided into two or three sectors, complete with stirrers, all made of stainless steel.

The internal sections are communicating through a labyrinth in order to guarantee the correct dissolution, homogenization and storage of the polyelectrolyte.